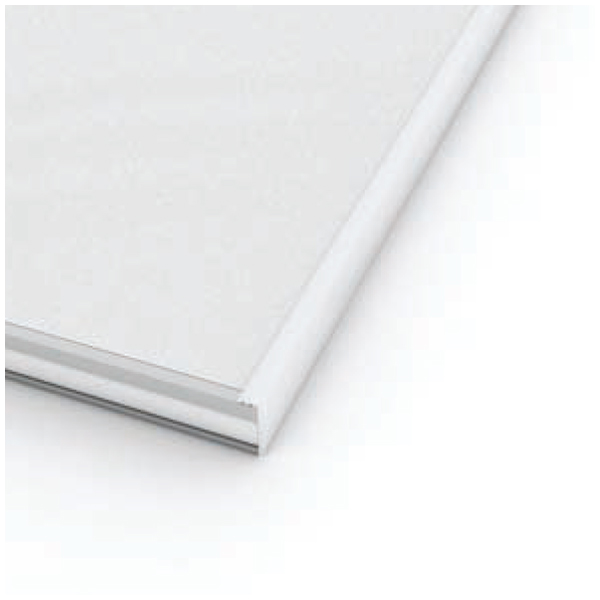

Lab Top

Assembly Type

Material and Specification

- Upper Part; Frosted TemperedGlass (51) I Phenolic Laminate Panel(5D

- Lower Part ;TrussStructured Assembly AL Profile by Anodizing

- Dimension ;(1200,1500,1800)mm x (650,750,800,900)mm x 25mm

Feature

- AssemblyType for Proper Selection BasedOn LabTopMaterials

- FrostedGlass for Prevention of Dazzling to the Eyes

- 4-Side Molding for Prevention of Edge Cracking and Protecting Film for Prevention of Scattering

- ChemicalResistant and High Durable Phenolic Laminate Panel

One Body Type

Material and Specification

- 20T TRESPA top latJP1US / 201Phenolic Laminate Panel

- Dimension:(1200,1500,1800)mm x (650,750,800,900)mm x 20mm

Feature

- EBCTechnology:Non-porousat theSurface andProtectingMicrobes

- Dry Forming :LaminatingSpecialCoated Rgure Paper and Impregnated Kraft-Paper and thenpressing at High Pressure and Temperature

- ChemicalResistant on the Basis of Test Method EN438

- BioResistant on the Basis of Test Method JIS Z 2801:2000

- ChemicalResistant and High Durable Phenolic Laminate Panel

Frame

Material and Specification

- Front & Back Part :AL Profile 40 x 60 mm

- Over2T(6063-T5)

- CombPatterned AL Profile by Anodizing

- VerticalPart ;AL Profile 40 x 60 mm

- Over 2T (6063-T5)

- CombPatterned AL Profile by Anodizing

- UpperSide Part :AL Profile 40 x 80 mm

- Over2T(6063-T5)

- CombPatterned AL Profile by Anodizing

- LowerSidePart:ALProfile17.5x21mm

- Over2T(6063-15)

- ALProfileby Anodizing

Feature

- HighChemicalResistant,Anti-corrosion andStrengthImprovement by Oxidation-aluminum Rim Formed from Anodizing on the Surface

- Much More BeautifulRound VerticalAluminum Frame thanSteelFrame

- Considering Operator’sSafety inLab by Applying Round Frame WhenInstall ing 2Tables

- Not Generating Toxic Substance likeFormaldehyde and Using the Materials 100% Recyclable

Skirt

Material and Specification

- Rear Part:EGISteelI

- 1.6T

- Powder Coating(Usage of Acid Resistant Epoxy Paint)

- Front Side : Polypropylene

- 6T (MDF) /5T (Phenolic Laminate Panel)

- Back.Side :EGISteel

- 1T

- Powder Coating(Usage of Acid Resistant Epoxy Paint)

Feature

- Applying Chemical Resistant and Durable High-Density Phenolic Resin Laminated with Special Coated FigurePaper andImpregnated Kraft-Paper and then pressed at High Pressure andTemperature (Front Side)

- Easy to Install or Dismantle Electric and Gas Supply System andEasy Maintenance

- Great Finishing and Anti-corrosion

- NoRisk.of Solvent Poisoning,Long-lasting Coated and Very SmoothSurface

- High Chemical Resistant,Anti-Corrosion and Strength Improvement by Oxidation-aluminum FilmFormed from Anodizing on the Surface

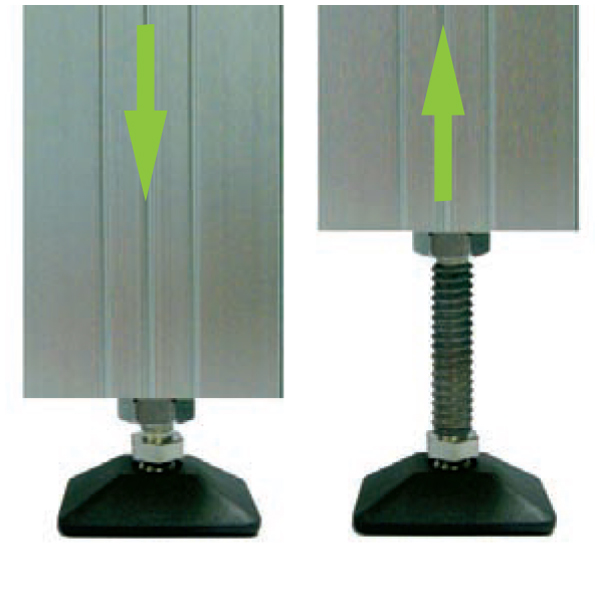

Foot base (Levelling foot)

Material and Specification

- Upper Bolt :SS400 HexagonalPole13mm

- Zinc Coated

- Lower Part :ABS + Nylon Resin

- Maximum Loading capacity: 400k.g

- Adjustable Angle up to 15 degrees

Feature

- Adjustable Angle for Uneven Floor

- Height Adjustable

- Impact Resistant,Thermal Resistance and Non Deformation at High Temperature

Socket panel (type1 /type2)

Material and Specification

- Upper Finishing:ABS

- Socket : PP ST

- Body:ALProfile 98x98m

- 2.5T (6063-TS)

- Coated Surface by Anodizing

- Lower Finishing:EGI1.6T

- Component:220V /100VI LAN /TEL Available

Feature

- Hinged Cover for Protecting Liquid and Reagent from Going into theSockets

Utility frame & Shelf

Material and Specification

- Upper Finishing :AL Profile 200 x 20 mm

- Coated Surface by Anodizing

- Frame (Exterior) :ABS 2T

- Frame (Interior) :ABS 2T

- Utility Part:AL Profile 60 x 25 mm

- Shelves:AL Profile I EGI1.6T

- 400mm (Center Type)

- 300mm (Side Type)

- Guide Pipe:SUS30412.7 mm

Feature

- The Best Usage of Under Space of Tables for Water,Gas,Electricity Supply System from Ceiling or Floor

- Highly Durable AL Profile and High Loading Capacity

- With the Assembly Structure,Very Easy to Adjust the Height of Shelves and Easy to Secure Loading Space

- SUS Guide Pipe Installed for Protecting Materials Falling Down